Survey

Marine Results International’s inspection techniques and procedures have evolved through our consultation with the industry, amongst them designers, manufacturers, race teams, insurers and authorities such as the Maritime Coastguard Agency and Germanischer Lloyd.

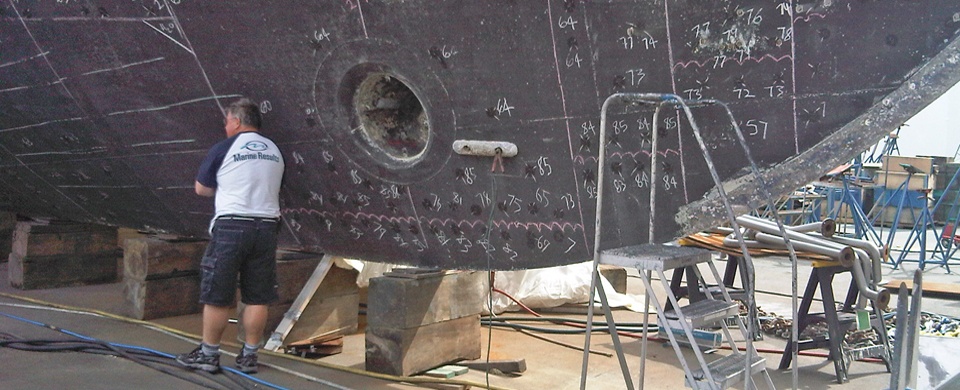

Inspections can be made during the build process, pre-delivery, routine surveys, damage inspection or post-repair inspection.

Marine Results International works closely with associate company International NDT, which was founded in 2019 by Marine Results’ technical specialists to provide Non Destructive Testing services which include modelling, mechanical analysis, expert witness, in depth evaluation and interpretation of NDT results ‘effect of defect’.

While International NDT works on our behalf to inspect all other aspects of a yacht and appendages, Marine Results continues to carry out inspections of masts and rigging during the course of our servicing work. We use a range of methods including ultrasonic testing and dye penetrant testing.

Certification

Marine Results inspectors hold qualifications at NDT Level 2 including:

- ultrasound (metallic, welded component, pipe and plate and composites)

- bond testing (cored laminates)

- penetrant testing

All operator training is to an aerospace inspection standard.